Industrial automation is the use of control systems for operating equipment such as machinery, plants processes, packaging lines,… with minimal or reduced human intervention. Some processes have been completely automated.

To make industrial automation feasible you need PLC’s (hard or soft). PLC’s are capable to interact at different situations. Depending on the input signals and the program in the plc’s, they adapt their output signals and therefore also the process.

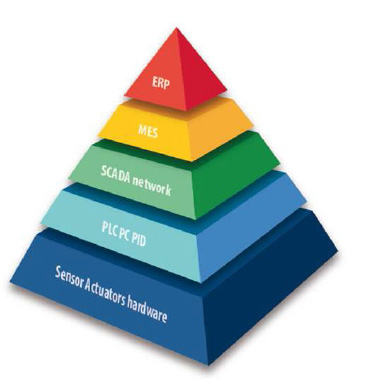

Industrial automation can be divided in different layers. From ‘shopfloor’ till ‘topfloor’. A brief overview can be seen in the layer model:

Layer 5: ERP LAYER = Enterprise Resource Planning Applications accross different departments/plants. E.g. centrale database for purchase orders

Layer 4: MES LAYER = Manufacturing Execution System E.g. Batch systems to initiate the different recipes.

Layer 2-3: CONTROL & SCADA LAYER = PLC’s and remote IO units + visualization for operators at the Scada screen and control of the proces

Layer 1: PROCESS LAYER = includes the field devices (valves, pumps,instrumentation,…)

DNE can help you with your automation projects. This can be in different ways depending on the needs you have:

- first advice for automation projects to startup the project

- complete definition of automation requirements

- total project management of automation projects

- rebuild of obsolete automation systems to new automation systems

- ...

DNE has more then 10 years experience in automation projects.

Besides industrial automation, DNE has also knowledge of IT related topics. E.g. Databases, Office Automation, Visual Basic, Website design, SQL, Networks, Home Automation, ...

Don't hesitate to contact me to see what is feasible for your challenges.